Assets and machines are the core strength of any manufacturing industry. With Industry 4.0, asset condition monitoring is becoming increasingly common across industries to ensure the safe and sound functioning of assets and improve efficiencies.

Asset Condition Monitoring is the process of monitoring each parameter of conditions in equipment or machines to identify a notable change that is indicative of developing a possible failure. It helps to identify machines’ run-time and downtime status, maintenance status, and health based on a few specific parameters like vibration, noise, fuel requirement, temperature, etc. It monitors all the possible parameters that are required to keep a machine in a better condition.

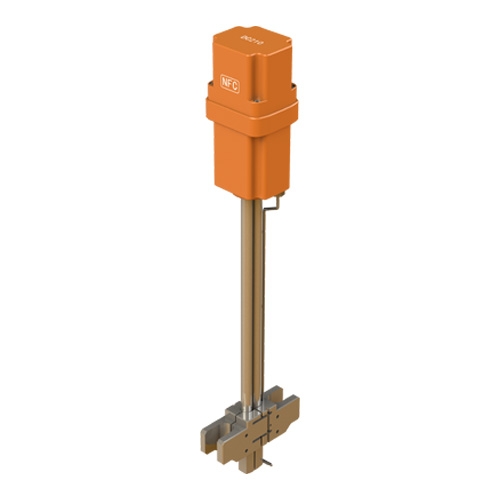

Condition monitoring techniques are used on a range of equipment, including rotating machinery, auxiliary systems and parts such as compressors, pumps, motors and presses.

Based on non-intrusive sensors, extremely low-power technology, long-life and replaceable internal batteries, and reliable wireless data transmission, our solutions are designed for easy installation and continuous operation without maintenance for years in harsh environment. Users can remotely monitor the status of the assets, receive early warnings and alarms of failures, and track progressive changes over time.

Within manufacturing industries, the following sensors from our portfolio are often used:

· Vibration sensors: Each vibration sensor integrates high-performance piezoelectric and MEMS vibration sensor and temperature sensor to collect the vibration signal of the device faithfully and accurately, use analytical algorithms to calculate a wide range of characteristic values, and transmit original waveform and characteristic data to remote monitoring system.

· Pressure sensors: Our wireless pressure sensors use glass micro-melting technology and measures pressure with high precision and low noise.

· Temperature sensors: Our temperature sensors support platinum thermal resistance probe PT100 and various types of thermocouple probes to suit different applications.

· Blot loosening sensors: Our wireless bolt loosening sensors monitor the tightness of bolted joints.

Our solutions increase the safety and longevity of critical assets, reduce downtime by optimizing operation and maintenance activities, and help drive smarter, faster business decisions for industrial companies.

Application Cases:

· Vibration Monitoring System Deployed in Steel Plant