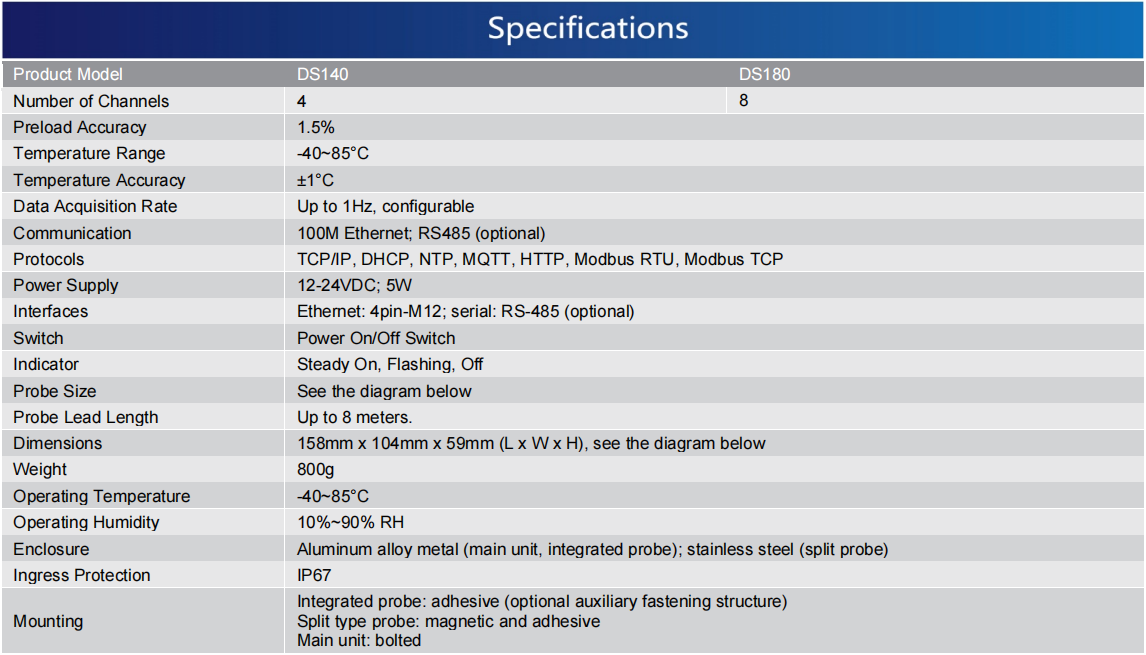

DS Series Bolt Preload Acquisition Devices

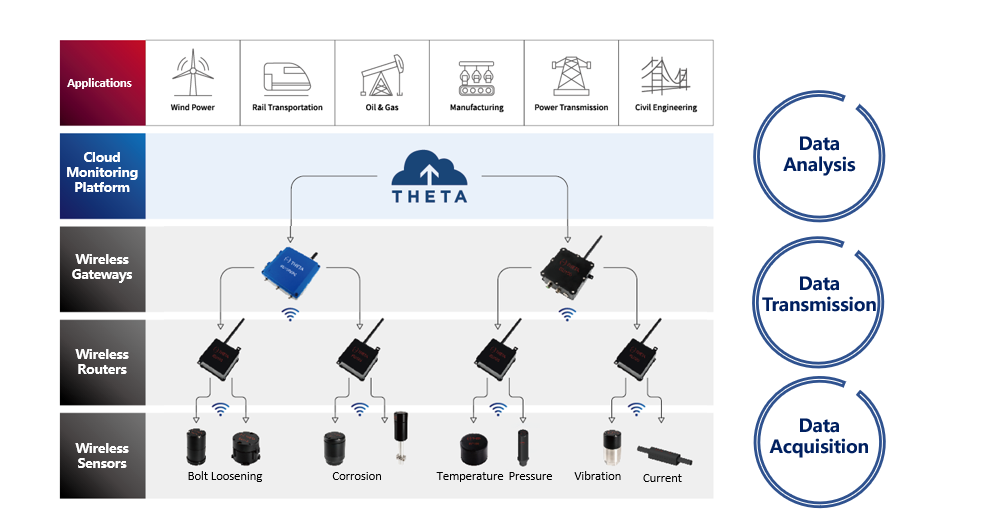

The DS series bolt preload acquisition devices are industrial-grade devices designed specifically for monitoring the health status of critical bolts in industrial equipment. The devices feature resistance to interference, high accuracy, and durability, making them suitable for long-term operation in harsh industrial environments, including wind power foundation anchor bolts, tower bolts, blade bolts, water turbine fastening bolts, steel structure bridge fastening bolts, and more.

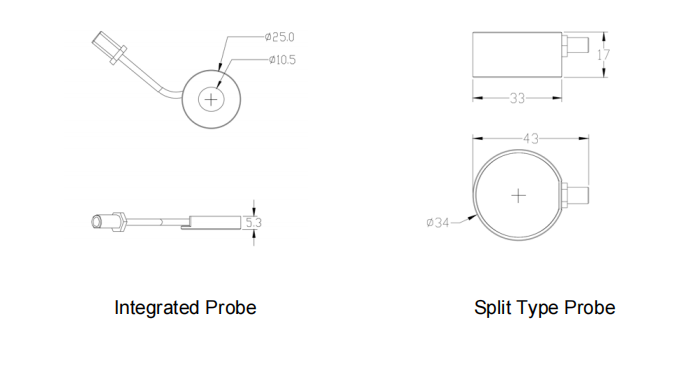

DS140 can connect up to 4 probes, while DS180 can connect up to 8 probes. There are two types of probes: integrated and split type. The integrated probes are ultra-thin and easy to install, making them suitable for environments where disassembly is not required or installation space is limited. The split type probes can be easily removed without affecting the maintenance of the bolts.

The device uses ultrasonic technology to accurately measure the time of the reflective ultrasonic waves. Additionally, each probe is equipped with a temperature probe to measure the surface temperature of the bolt. By applying a temperature compensation algorithm, the device can measure accurately and reliably the bolt's preload (axial stress) at different temperatures.

The sensor data is transmitted to a remote monitoring platform. Users can remotely monitor the bolt preload and receive timely alerts in case of loosening, fatigue, or fracture of the bolt. This allows continuous tracking of the entire process of bolt loosening, ensuring safe equipment operation, preventing unplanned downtime, and reducing maintenance time and costs.

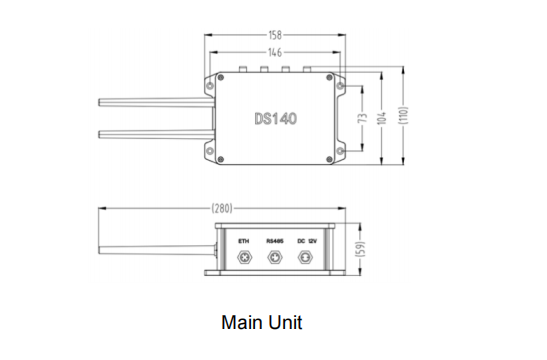

Enclosure: